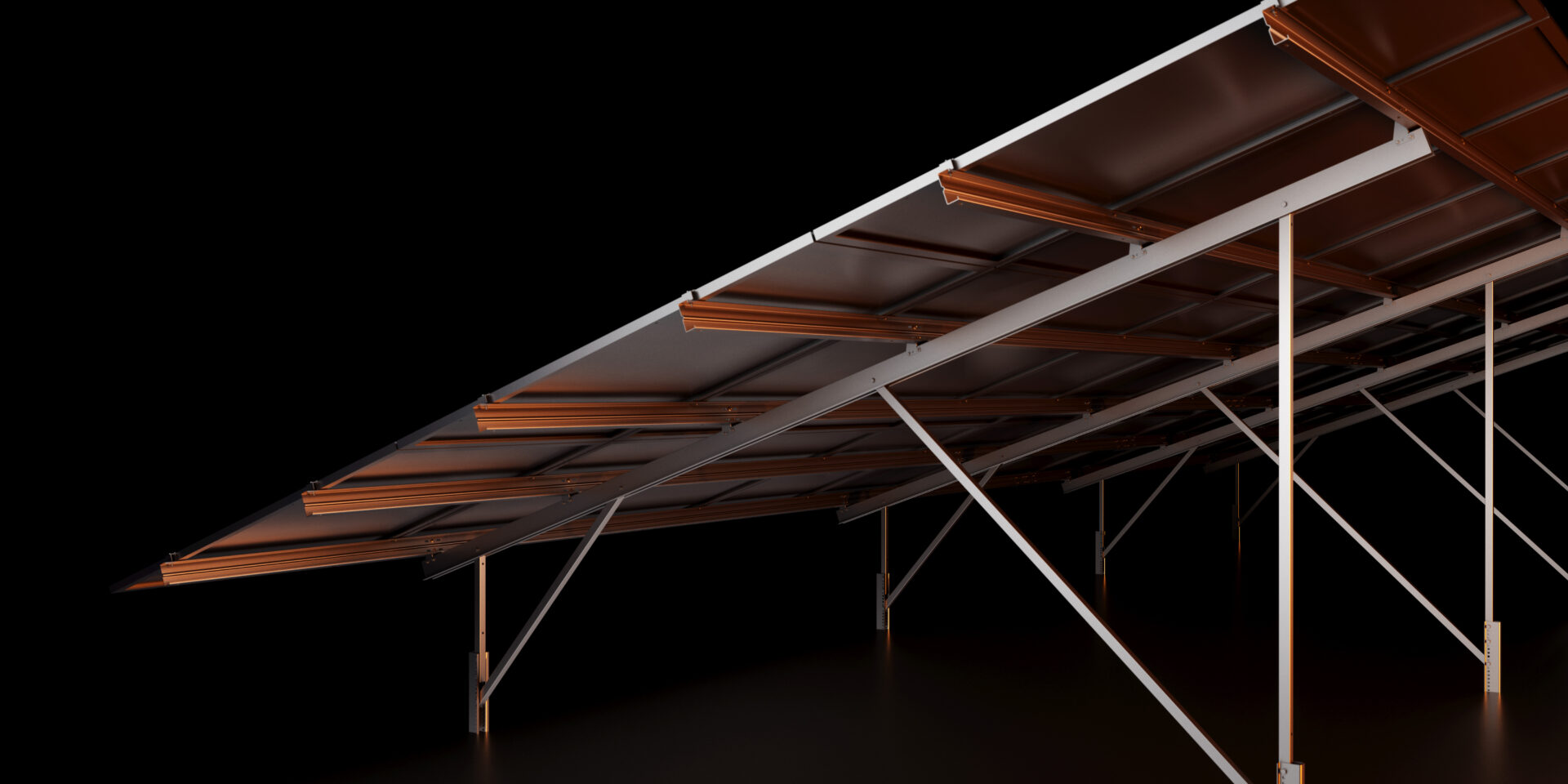

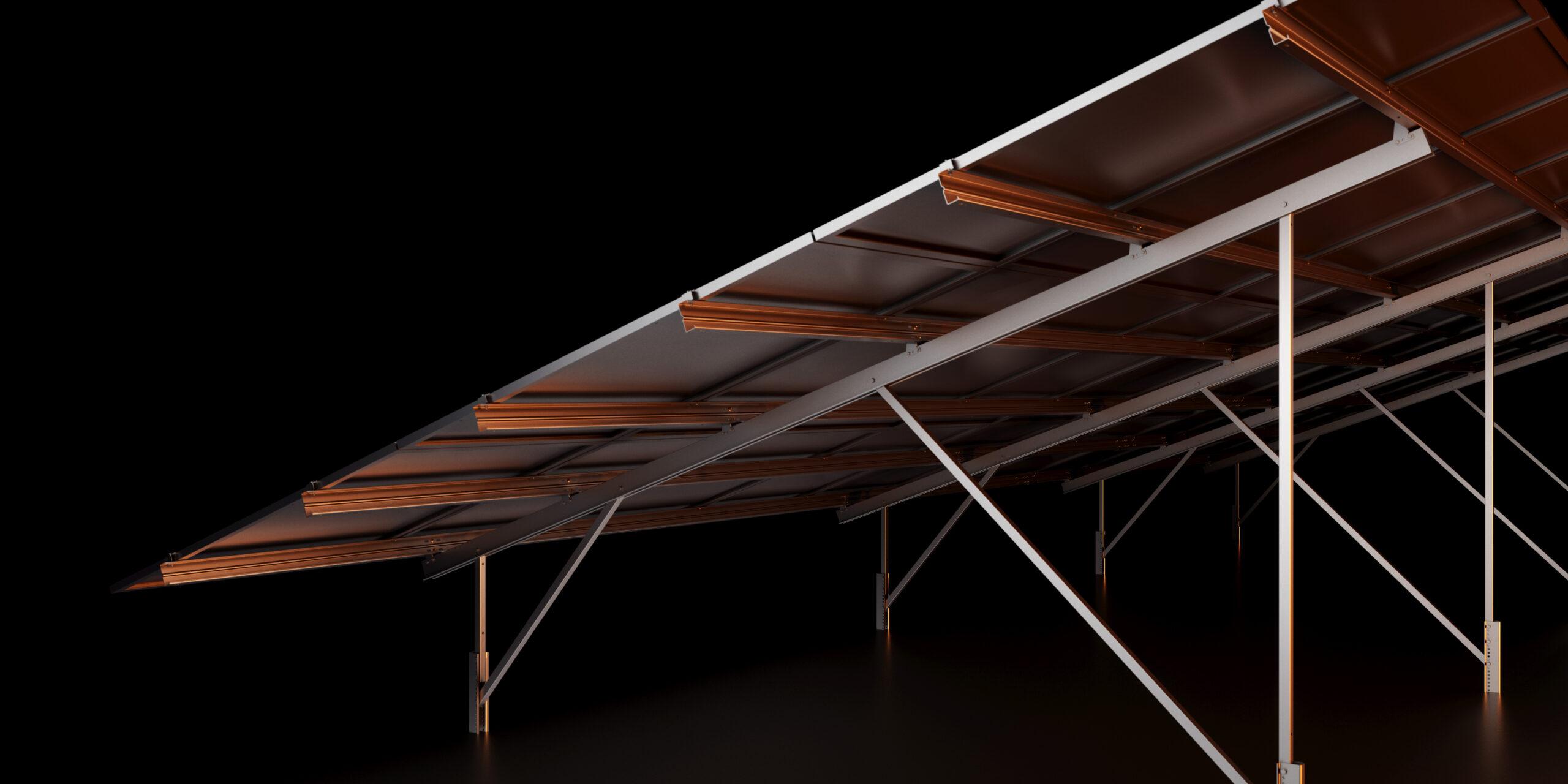

Lüneburg, Germany, 2.7 MWp

Lüneburg landfill, Germany

We have already mastered landfills with extreme challenges posed by the building structure with our Sigma systems - here is an example from Lüneburg.

| Project name | Lüneburg |

| Project location | Germany |

| PV capacity | 2.7 MWp |

| Project start | 2012 |

| Frame system | Project-specific solution |